Four de laque en poudre de type tunnel Produits populaires

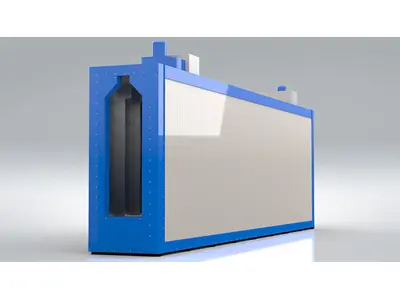

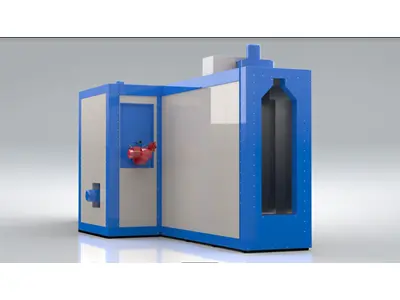

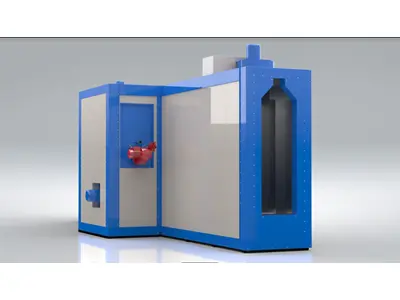

Tunnel Type Powder Coating Oven

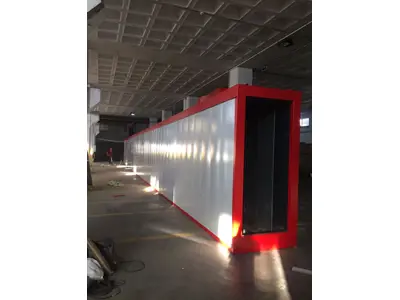

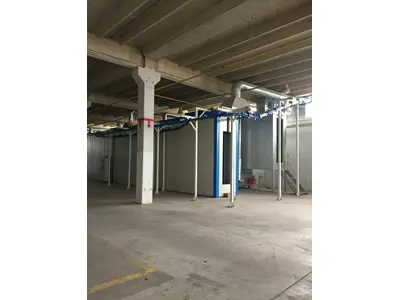

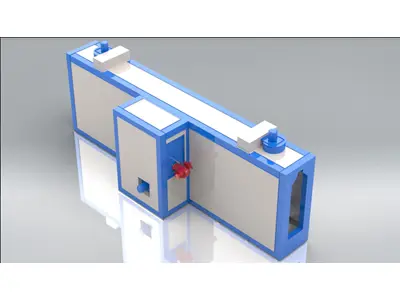

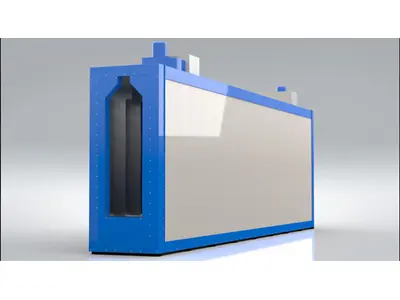

One of the most advanced technologies that combines quality, efficiency, and speed in industrial production, tunnel type powder coating oven is designed to perfectly cure the powder coating applied to the surfaces of metal, wood, and other materials. The tunnel structure of the oven allows the painted parts to move continuously, ensuring progression within temperature equality. This period ensures that the powder coating adheres to the surface in a homogeneous manner, guaranteeing a durable, smooth coating. Tunnel type powder coating ovens, which are indispensable in many sectors from automotive to white goods, furniture, and construction, elevate the efficiency of enterprises with superior coating quality and high production capacity.

Tunnel type powder coating ovens stand out in industrial painting processes with their unique advantages. These ovens, with their tunnel structure that allows parts to move constantly within the furnace, enable fast and consistent results even in large-scale productions. Equipped with advanced technology, these ovens ensure the optimal curing of each part with precise temperature control, guaranteeing the powder to harden on the surface perfectly, resulting in a long-lasting coating. These ovens draw attention with their smart designs that provide energy efficiency. With heat recovery systems and optimized air flows, energy consumption is minimized, reducing operating costs and contributing to environmental sustainability. Tunnel type powder coating ovens offer flexible adjustment options for parts of different sizes and shapes, allowing businesses to offer a wide range of products. Tunnel type powder coating ovens not only ensure efficiency but also contribute to the environmentally friendly execution of production processes. The solvent-free powder coating method eliminates chemical emissions that harm the environment and enables working with recyclable wastes. These features make tunnel type powder coating ovens an eco-friendly production tool.

Tunnel type powder coating ovens have a wide range of applications and play a significant role in various sectors. In the automotive sector, these ovens offer ideal solutions for protecting vehicle parts with durable and aesthetic coatings. In white goods production, tunnel type powder coating ovens are preferred for perfectly painting metal surfaces of refrigerators, washing machines, and other home appliances. In the furniture sector, these ovens play a critical role in painting not only metal furniture parts but also decorative elements. In the construction and electronics sectors, these ovens are one of the fundamental elements of coating processes that ensure long-lasting and durable products. Tunnel type powder coating ovens are indispensable for factories carrying out large-scale production, as they have the capacity to produce at high speeds and in large quantities.

Tunnel type powder coating oven is a top-level solution for businesses seeking quality, speed, and efficiency in modern industrial production processes. These ovens significantly enhance the aesthetic and functional value of final products by ensuring that powder coatings cure flawlessly and durably on the surface. With their tunnel design and advanced technology, these ovens provide consistent and excellent results even at high production volumes. In addition, by offering energy efficiency and environmentally friendly production features, they help businesses reduce costs and minimize their environmental impact. Widely used in various sectors such as automotive, white goods, furniture, construction, and electronics, tunnel type powder coating ovens add value to your production line and significantly enhance your competitive advantage in the market.

Tunnel Type Powder Coating Oven Prices

The prices of tunnel type powder coating ovens can vary depending on various factors such as the size, capacity, the technology used, energy efficiency, and automation level of the oven. Additionally, features such as heat recovery systems, temperature control, installation characteristics, and customization options of the oven also play a crucial role in affecting the cost. These ovens, which vary according to production needs, are generally evaluated and priced on a project basis. Tunnel type powder coating ovens can be available at average prices around {fiyataraligi}. Therefore, to determine the most suitable tunnel type powder coating oven price, it is recommended to make a detailed evaluation with supplier companies and get a customized offer according to your needs. This process helps you manage your investment most efficiently and achieve the highest performance in the long run.

To meet your needs for a new or second-hand tunnel type powder coating oven, you can purchase from reliable manufacturers or authorized suppliers through makinaturkiye.com and also get support from authorized service providers.